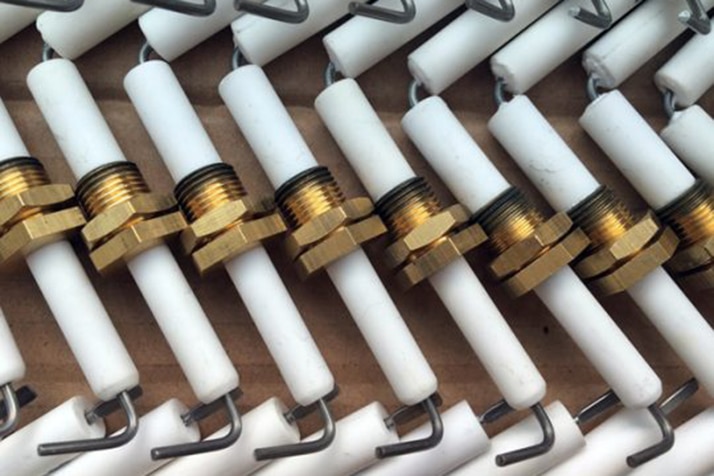

- Gli adesivi ceramici Aremco per alte temperature sono unici nel loro genere grazie alla particolare formula inorganica e costituiscono una soluzione sicura per saldare e sigillare ceramica, metalli, quarzo, grafite, materiali in fibra e compositi per applicazioni fino ad oltre 1700 °C.

Adesivi Ceramici Aremco per saldare e sigillare ceramica, metalli, quarzo, grafite, materiali compositi ed in fibra in applicazioni fino ad oltre 1700 °C

- Gli adesivi ceramici AREMCO mostrano elevata resistenza termica ed elettrica e rappresentano la soluzione a problemi di difficile soluzione con l’impiego di Epoxy o prodotti analoghi a base organica.

- Gli adesivi ceramici AREMCO sono pronti all’uso dopo curing tra i 93°C e 260°C. Si tratta in gran parte di adesivi ceramici a base acquosa che non emettono gas dopo la ricottura.

- Gli adesivi ceramici AREMCO sono inoltre conformi alle norme di tutela dell’ambiente, sono non infiammabili e non contengono solventi organici volatili.

Applicazioni tipiche :

- Resistenze Elettriche

- Resistenze Ballast

- Connettori per Fibre Ottiche

- Sistemi ad iniezione di gas

- Lampade alogene

- Elementi riscaldanti

- Lampade ad alta intensità

- Riscaldatori a resistenza