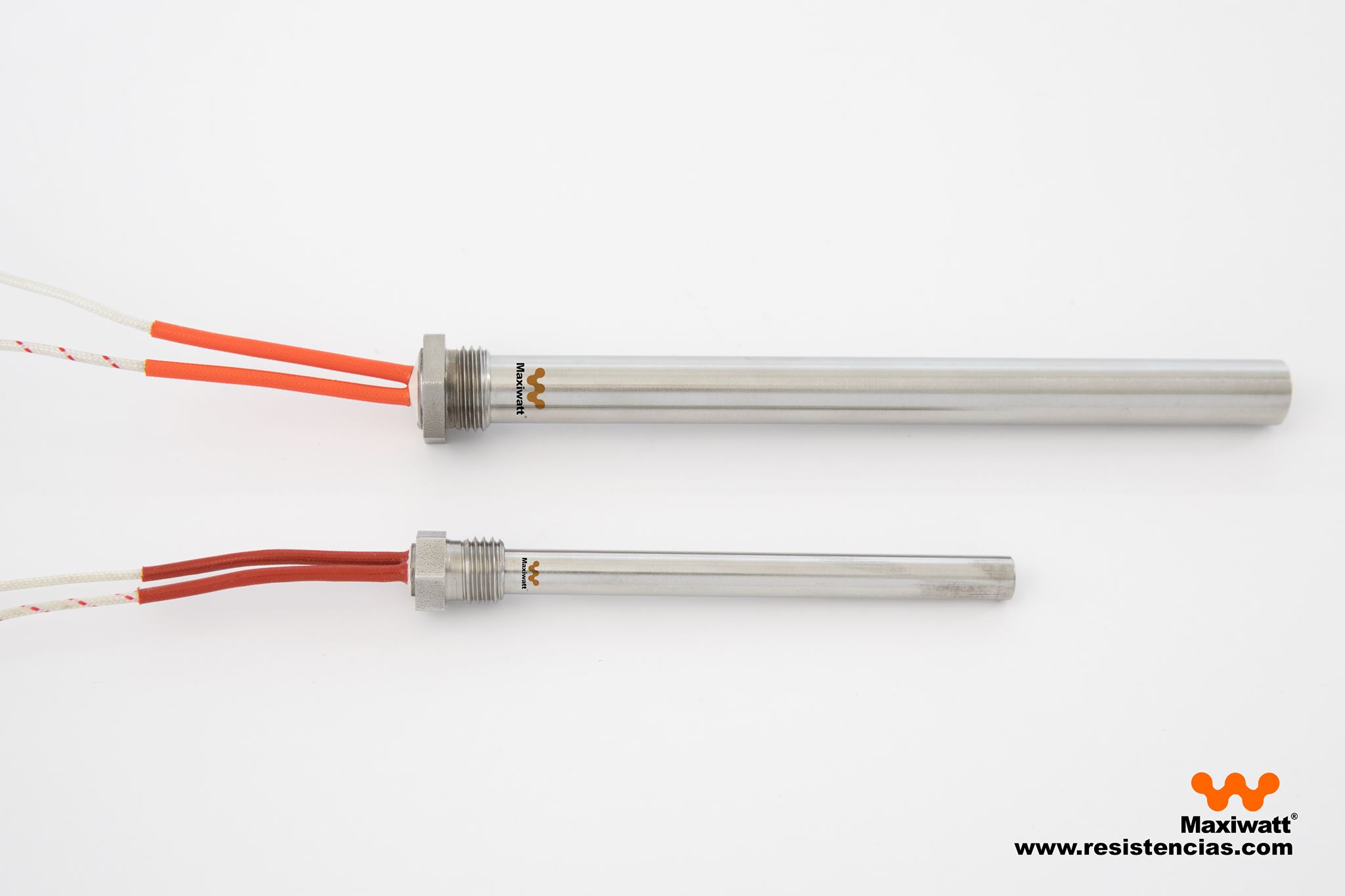

Maxiwatt produce riscaldatori a cartuccia con densità di potenza molto elevate sulla superficie della guaina. Infatti l’elemento riscaldante in nichel-cromo è molto vicino alla superficie esterna. Un sottile strato di ossido di magnesio fortemente compresso isola elettricamente la resistenza riscaldante dal metallo della guaina per consentire un’elevata conducibilità termica.

Riscaldatori a cartuccia per i settori della Plastica e Microelettronica. Tecnologia costruttiva con densità di potenza elevata e temperature fino a 1000°C.

Le dimensioni standard di questi riscaldatori a cartuccia sono conformi alle norme DIN. I nostri sono impiegati diffusamente in molte applicazioni legate alla formatura della plastica come per esempio riscaldatori a cartuccia per piani caldi, teste di trafile, cilindri, camere calde ed ugelli per iniezione di materie plastiche. Grazie alla tecnologfia di Maxiwatt la differenza di temperatura tra il filo e la guaina esterna è più bassa rispetto ad altri tipi di riscaldatori, ottenendo nel contempo massima precisione ed uniformità del riscaldamento.

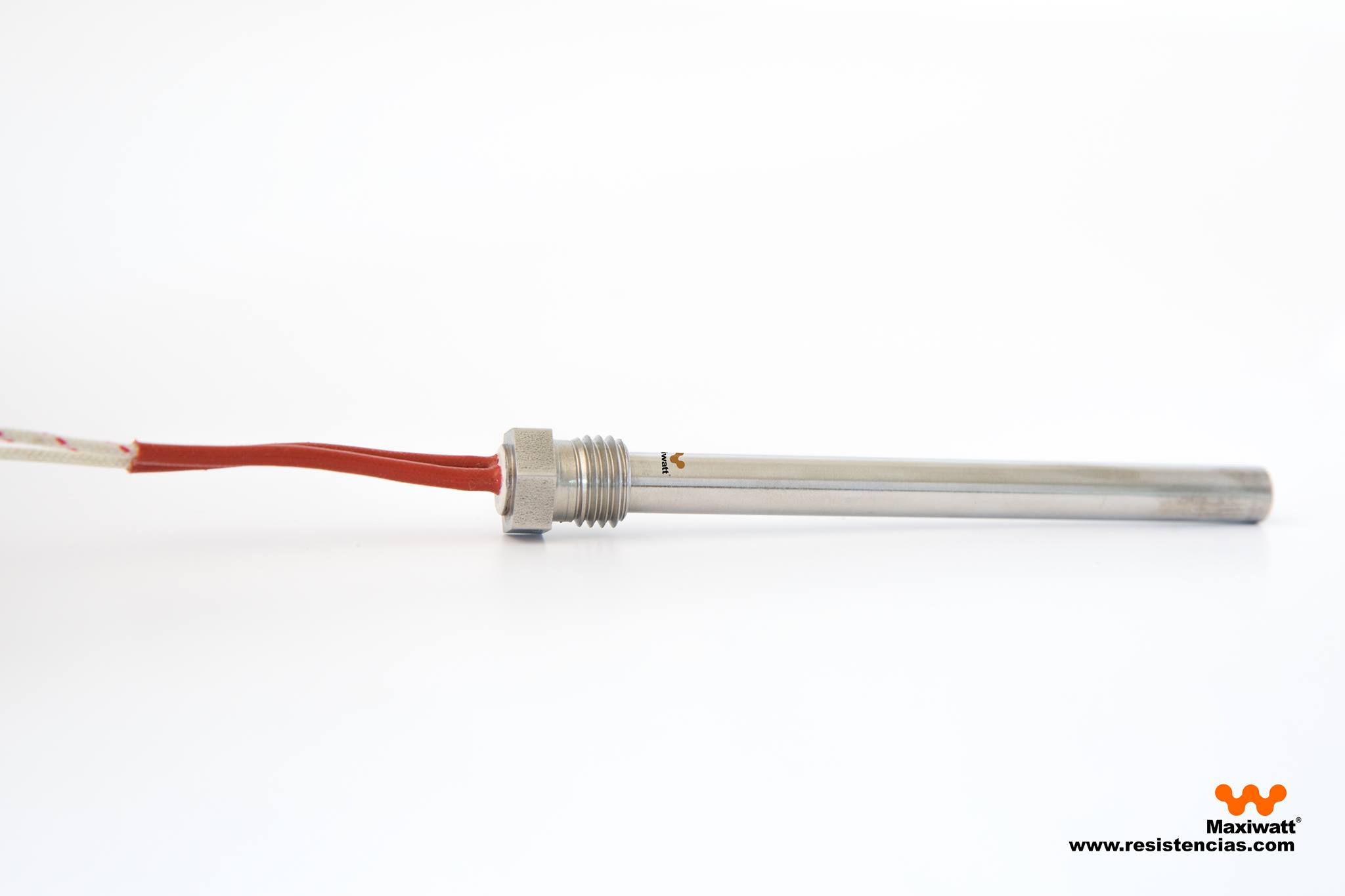

I cavi di alimentazione con isolamento in fibra di vetro sono flessibili ed il punto di giunzione è collocato all’interno della cartuccia, mentre l’estremità del riscaldatore a cartuccia è saldata a TIG alla guaina ed impervia ai gas.

La guaina del riscaldatore viene rettificata alle macchine utensili per ottenere tolleranze molto ristrette sul diametro (da -0.02 mm fino a -0.06 mm). Sono possibili realizzazioni che prevedeno zone di riscaldamento differenziate e con elevatissima precisione e ripetibilità.

I riscaldatori a cartuccia possono integrare termocoppie di tipo J (ferro/ costantana) o tipo K (chromel/alumel). Nella versione standard, con termocoppia tipo J, il giunto caldo é posizionato nella posizione tipo TCJ1. I riscaldatori a cartuccia ad alte performance rappresentano il più recente sviluppo tecnologico di un prodotto di eccellenza

La guaina del riscaldatore viene rettificata alle macchine utensili per ottenere tolleranze molto ristrette sul diametro (da -0.02 mm fino a -0.06 mm). Sono possibili realizzazioni che prevedeno zone di riscaldamento differenziate e con elevatissima precisione e ripetibilità.

I riscaldatori a cartuccia possono integrare termocoppie di tipo J (ferro/ costantana) o tipo K (chromel/alumel). Nella versione standard, con termocoppia tipo J, il giunto caldo é posizionato nella posizione tipo TCJ1. I riscaldatori a cartuccia ad alte performance rappresentano il più recente sviluppo tecnologico di un prodotto di eccellenza